1300+ patented technology innovation, 95% mold self-made

Liquid silicone mold technology

Hot runner die technology

Plastic waterway integrated molding mold technology

Bathtub molding mold technology

…

Liquid silica gel technology

Trivalent chromium plating technology

…

Glass easy cleaning technology

Multiple security techniques

Multiple express loading technology

…

Thermostatic spool technology

Hidden hardware technology

…

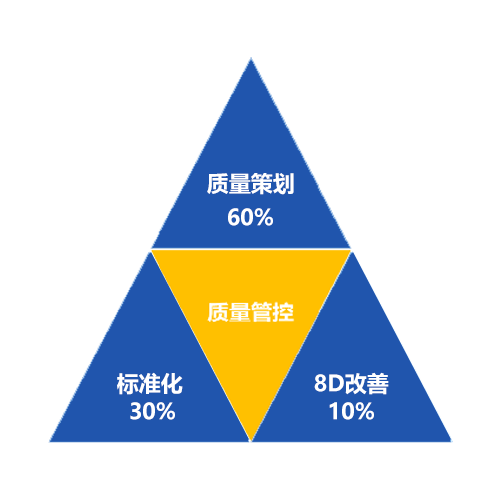

Strive for 60% quality planning +30% standardization +10% 8D improvement

Quality management system

Environmental management system

Occupational health and safety management system

North American certification

European CE Certification

China 3C Certification

…

APQP+PPAP management system

…

APQP+ Process audit + Incoming inspection

…

PFMEA+ Quality control plan +CPK/SPC+Poke-Yoke

…

Lean+Kaizen

…

To meet the major sanitary standards in the global market, 80-100% product testing capacity

| Shower | Faucet | Shower room | Bathtub | |

| Chinese standards | 100% 1.GBT23447-2009 2.GBT 23448-2019 | 100% 1. GB18145-2014 2. GB 25501-2019 3. GB 28378-2019 4. QB T 2806-2017 | 100% QB 2584-2007 | 100% 1. JCT 779-2010 2. QB2585-2007 |

| American standard | 100% 1. ASME A112.18.1-2018 2. EPA Watersense | 90% 1. ASSE 1016-2017 2.ASME A112.18.1-2018 | 90% IAPMO IGC 154-2012 | 80% IAPMO IGC 244-2015 |

| European standard | 100% EN1112-2008 | 100% 1. EN1111-2017 2. EN817-2008 3. EN200-2008 | 100% EN 14428-2015 | 100% EN 14516-2015 |

| Australian standard | 100% AS 3662-2013 | 90% AS NZS 3718-2005 | 90% ATS 5200.050-2005-SH-08 | 80% AS-NZS 2023-1995-SH |

Ten million levels of production capacity rely on to meet the needs of customer orders

The annual production capacity is over 28 million sets

…

The annual production capacity exceeds 1.6 million sets

…

The annual production capacity is over 150,000 sets

…

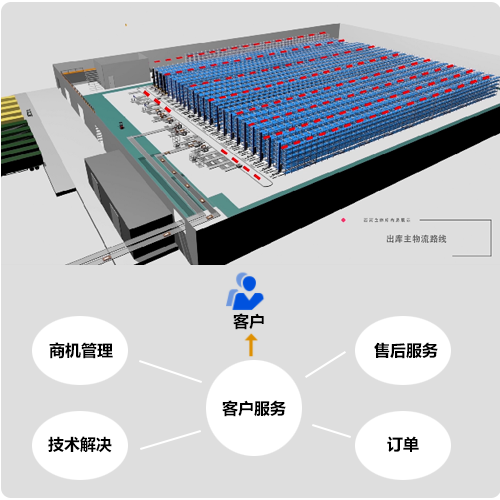

Build a multi-system collaboration customization center including Insight, SAP/PAC, MES, WMS.

Online And Offline Activities For Attracting Potential Consumer

Modeling / Space design

Product Selection/Customer Concept Design

Quick Ordering And Real-time Quotation

Order Processing

(BOM/Processing/ Drawing)

Automatic scheduling 、 Equipment docking

Picking、Production、Delivery

Distributor Picking Up , Delivery And Distribution

User star rating

Won a number of + international top bathroom brand customers and partners service honor certificates/trophies

Business - Development - Quality Golden Triangle technology management system

…

Set up a professional order and after-sales service team

…

Focus on environmental protection, renewable energy use, energy conservation and emission reduction, and resource recycling in enterprises and supply chains.

Official WeChat

Official WeChat